Innovative Injection Molding Tool Design for Precision and Efficiency

A Trusted Partner in

Precision Plastic Manufacturing

Pacific Plastic Technology specializes in injection molding tool design that sets the standard for quality and reliability. Our tools are engineered to optimize production efficiency, reduce cycle times, and deliver high-precision plastic components tailored to your unique requirements. Whether you need a prototype mold or a production-ready tool, we have the expertise to deliver results that exceed expectations.

Precision Tools Built for Performance

Every project begins with meticulous tool design to ensure seamless manufacturing. Our approach focuses on:

- Custom Tooling Solutions: We design molds to meet your specific part requirements, from material selection to geometry and tolerances.

- Durable Tooling Materials: Our tools are crafted using high-quality materials to ensure longevity and consistent performance, even under demanding production conditions.

- Optimized Production: By leveraging advanced design techniques, we create tools that minimize waste and maximize efficiency.

Why Tool Design Matters in Injection Molding

The quality of the injection molding tool directly impacts the finished product. A well-designed tool ensures:

- Accurate dimensions and consistent part quality.

- Faster cycle times, improving production efficiency.

- Reduced maintenance and extended tool life.

At Pacific Plastic Technology, we understand the critical role that tool design plays in the success of your project, and we approach every design with precision and care.

Industries We Serve with Expert Tool Design

Our injection molding tool design capabilities cater to a wide range of industries:

- Automotive: Crafting tools for components like body side moldings, splash guards, and interior parts. Learn More

- Battery Components: Designing molds for lightweight, high-strength components. Learn More

- Power Generation: Delivering tools for durable, heat-resistant parts. Learn More

- Industrial Products: Supporting a variety of industrial applications with robust tooling solutions. Learn More

- Firearms: Creating precision molds for firearm receivers and other critical components. Learn More

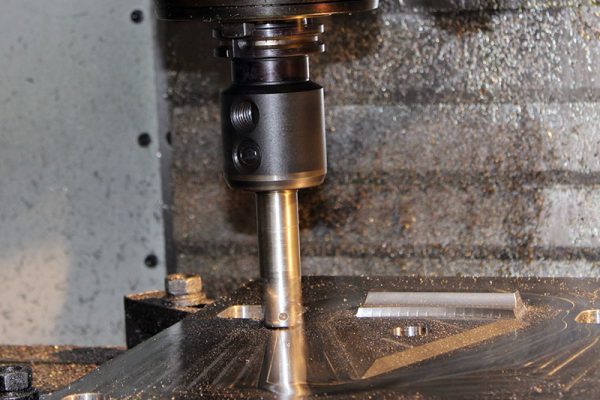

Advanced Capabilities for Injection Molding Tool Design

We utilize cutting-edge tools and techniques to achieve superior results:

- CAD/CAM Software: Advanced design software ensures precise mold designs tailored to your specifications.

- Design for Manufacturing (DFM): Our team collaborates with you to optimize part designs for efficient production and superior performance.

- Rapid Prototyping: Speed up development and validate designs with prototype molds before full-scale production.

Integrated Services for Seamless Production

Our injection molding tool design services are part of a comprehensive suite of solutions:

- Custom Injection Molding Learn More: We deliver high-quality molded parts from concept to production.

- Secondary Operations Learn More: Enhance and finalize your components with specialized finishing services.

- Assembly & Packaging Learn More: Streamline your production process with our end-to-end capabilities.

Why Choose Pacific Plastic Technology for Tool Design?

- Experience: Over 50 years of expertise in tool design and injection molding.

- Precision: Every tool is crafted to meet the most demanding specifications.

- Innovation: We leverage the latest technologies to deliver superior tools.

- Reliability: Tools designed for efficiency, durability, and consistent performance.